Sponsor

Experts

Media support

Conference materials

In the new realities, any project, if it does not develop and does not seek to increase the efficiency of the business, quickly becomes risky. The time for dreaming about factories is leaving, only a few will remain on the market who are able to create new projects or develop an existing business.

The owner, the manager constantly faces the problem of the availability of information about markets, technologies, and the quality of marketing. The world is changing rapidly, and with it, the agricultural sector is changing: those industries that only yesterday attracted investors are now relegated to secondary roles, and those that have recently stagnated are receiving a new impetus for development. Now, more than ever, it is important to respond quickly to changes in the competitive environment and market conditions in order to develop.

“Deep Processing of Grains – Sales Markets 2021-2023”: starch and corn oil are obtained from corn by wet grinding as the main production products, high-quality animal feeds are produced as by-products of production: gluten flour, gluten-free feed, corn extract, and corn pulp …

For deep processing, corn starch is directed in one of 4 directions: saccharification, polymerization, modification, and fermentation. At the output of the technology of saccharification of starch with subsequent physical processing, a wide range of disaccharides can be obtained, such as dextrose, glucose, fructose, maltose, which are a group of sweeteners (sugar substitutes). Disaccharides can be used to build complex molecules such as high fructose HFCS syrups and low-calorie sugar substitutes, or used as a primary raw material for many fermentation processes.

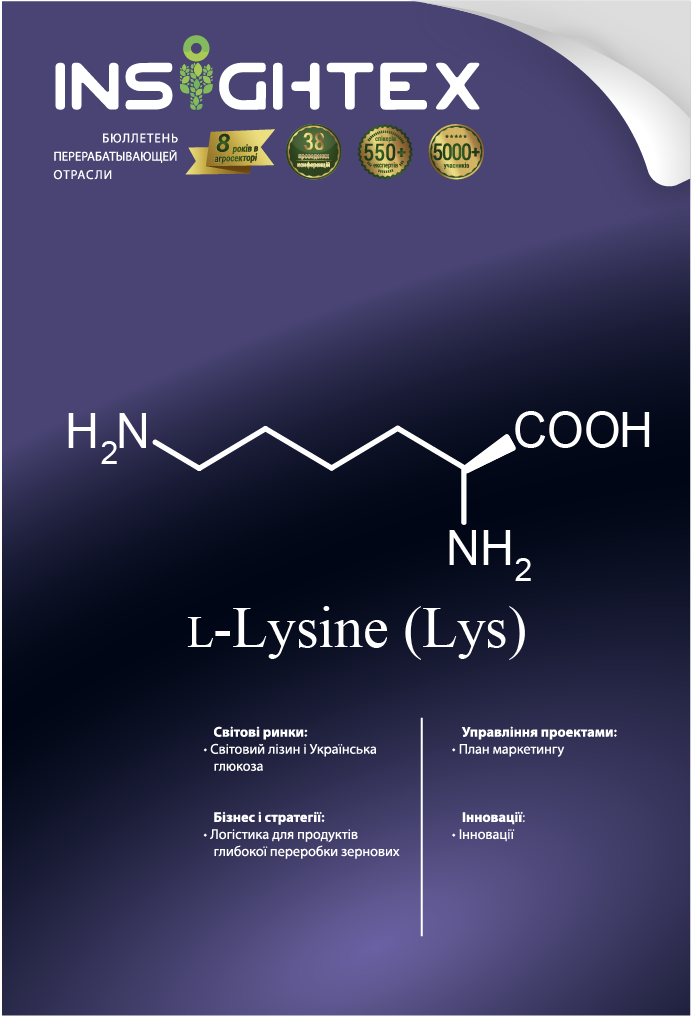

For example, using dextrose obtained from the deep processing of corn by the saccharification method, market leaders use fermentation to produce 11 basic vital amino acids (there are 20 of them in total). At the same time, the fermentation production of vitamins is gaining momentum, which will significantly reduce their cost and make vitamins commercially available for livestock purposes.

The range of modified starches is replenished every day, and there are thousands of them. The main technologies that change the native starch are extrusion, heat treatment, oxidation of starches, irradiation of starches with infrared rays, phosphorization of starches, etc. Modification of starches is carried out in order to better adapt the product to achieve functional properties. For example, without oxidized starch, it would be impossible to make ice cream, and in juices, modified starch is used to impart texture (pulp feel).

Today it would be impossible to imagine a world without polymerized starches. These are, first of all, tablets in a package suitable for swallowing. The supply of amino acids and vitamins of cattle in such a way that nutrients do not degrade in the rumen of ruminants, but reach the abomasum to perform work – this allows to significantly reduce the conversion of feed into milk and meat, and, consequently, reduce the cost of products. Polymerized starch is also a coating for furniture and doors for wood.

“From this small list of processed products, Ukrainian companies will be able to find a product to develop their own processing business.”